Production Equipment

In the process of development, we constantly introduce many high- end processing equipments from Japan, Switzerland and other countries, such as: WAIDA optical projec tion grinder SPG - W (PG/Japan), SEIBU M50B wire cutting (Japan), and Sodick AP200L oil wire cutting, and Sodick ALN400Gs wire cutt ing (Japan), Agie Charmilles CUT E350 wire cutting(Swit zerland), precision surface grinding machine (Taiwan) etc.

PG Grinding workshop

Wire Cutting workshop

Sodick Oil Wire Cutting AP200L

Coordinate Grinding Workshop

Seibu M50B Wire Cutting

Agie Charmilles CUT350 Wire Cutting

Surface Grinding

CNC Preparation Workshop

Mirror EDM Workshop

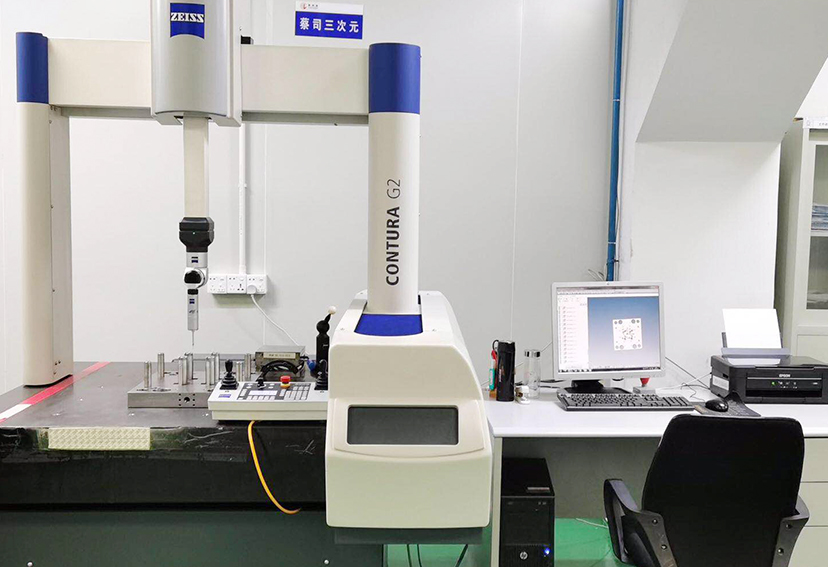

Quality Equipment

Quality assurance is a priority of our machining process from start to finish. Our highly trained personnel carefully monitor their work for accuracy and keep a watchful eye on production to maintain consistent results. Most importantly, we stay in close communication with the customer throughout the entire process to ensure quality, dependable results. No matter how large or small your order, we guarantee consistent part quality.

Nikon Optical Projector

Nikon Height Gauge

Rowell Hardness Tester